- Application Types:

- Combustion gas for FID Analyzers

- Carrier gas for GC and GC/MS-MS

- Reaction gas for ICP-MS

- Protection gas

- MOCVD or Gems Growing

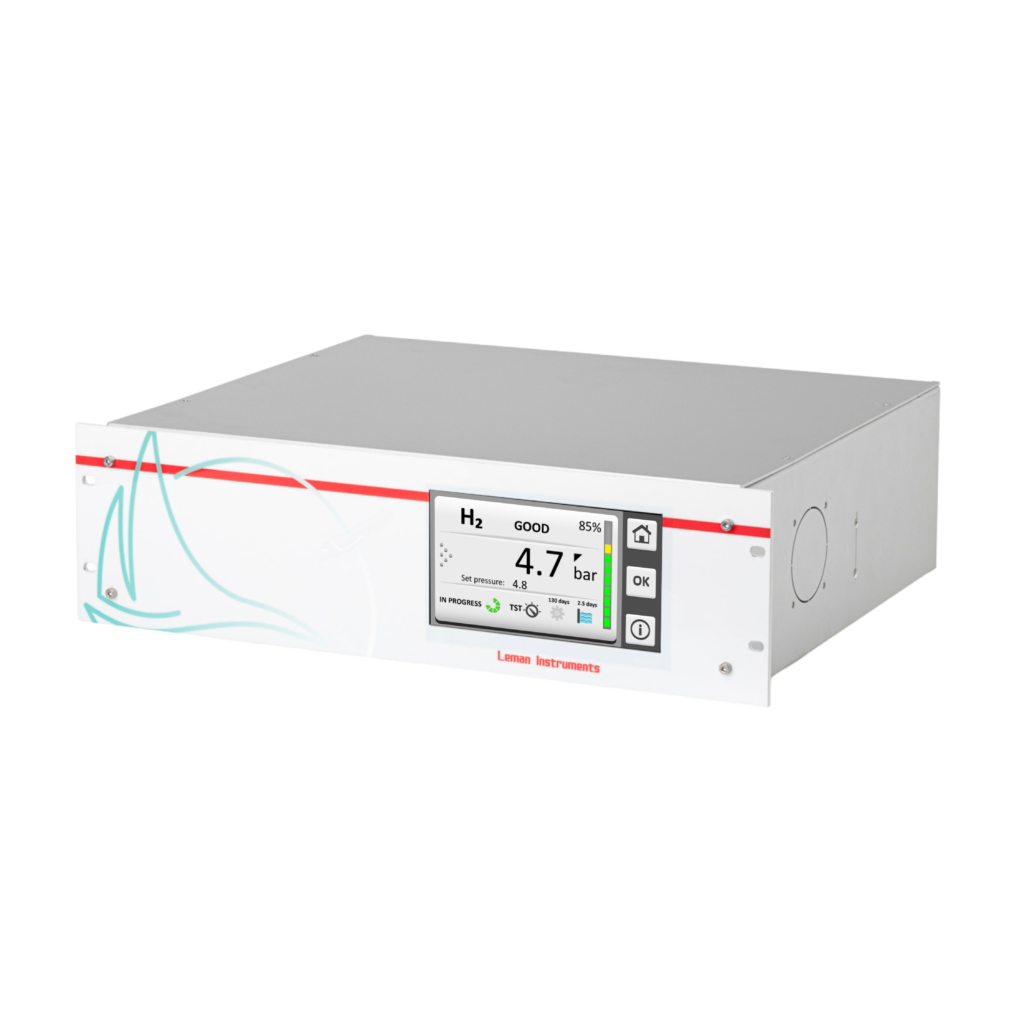

HYDRO70 R

LEMAN Instruments designed the HYDRO70R product line of Ultimate Purity Hydrogen generators to aliment FIDs & GCs, fuel cell, and crystal growing installations close to the consumer in an elegant 19” casing with full-color display and touchscreen.

Based on the field-proven Solid Polymer Electrolyte (PEM) cell technology, pure Hydrogen is produced at low pressure from electricity and high-quality distilled water. After production, H2 is dried and purified by an exclusive No-Maintenance Double Column Purifier module (PSA). H2 is available 24/7 with constant purity >99.99999%. Output pressure is regulated electronically and could be set from 0.5 to 7 bar. This process can be started on demand without a caustic solution.

Models with 100, 160, and 300 Nml/min H2 outflows are available.

Each instrument is equipped with high-performance communication interfaces, such as USB, RS485, and Ethernet, to create a very flexible gas network with local or central control.

Due to the software being focused on safety, automatic regulation, and intuitive and reliable communications, the HYDRO70R is easy to install, reliable, safe, and pleasant to operate.

Features

- Reduces in operation costs. Return on investment within 6-8 months.

- Improves resolution and detection limit versus Helium-only usage. Provides High-pressure stability.

- H2 is available 24/7 at constant purity. No contamination.

- Independent source of Hydrogen

- Remote control

- Low functioning noise

- Our product guarantees 100% safe operation with its internal leak-test, automatic shut-down, over-pressure valve, and current and voltage limits.

- No handling and storage of cumbersome gas cylinders. There is no cylinder rental fee.

Gas

Models | HYDRO70 R-100 HYDRO70 R-160 HYDRO70 R-300 |

LMP Outflow @1013 HPA / 20°C | HYDRO70 R-100: 0.100 LMP HYDRO70 R-160: 0.160 LMP HYDRO70 R-300: 0.300 LMP |

H2 purity |

|

Outlet Pressures | From 0.5 to 7 bar (7 to 102 psig) |

Site & Installation

Water quality |

|

Water source | By external 5L tank or Direct line deionized water consumption |

Water consumption | 12L water generates about 12 m3 of Hydrogen |

Safety | Overpressure valve; internal leak test; automatic shut down; maximum current limit, water quality |

Manual control | Through a 7” TFT-LCD color display with a touchpad located on the front panel. Display of major parameters, pressure, functioning status, and alarms. Intuitive navigation to functions by menus and sub-menus |

Remote control, Communications | • RS485 (Mod-Bus), USB • Through Ethernet 10/100 network • Logbook download by USB |

Input & Output fittings | Stainless steel 1/4″ OD compression |

Power supply | Automatic switching from 90 to 260 VAC, 47 to 63 Hz |

Power consumption (max at full flow) | maximum 150W |

Ambient temperature | +5 to +35°C, non condensing |

Dimensions & Weight

Dimensions cm / in | L: 35cm/1: 41.5cm/H: 12cm (3U) L: 13.7in /1:16.lin /H: 4.7in (3U) |

Net weight (kg/lbs) | 15kg/ 33lbs |