- Application Types:

- Combustion gas for GC

- Zero gas for HC calibrators

- Carrier gas for permeation tube systems

AERO50 R

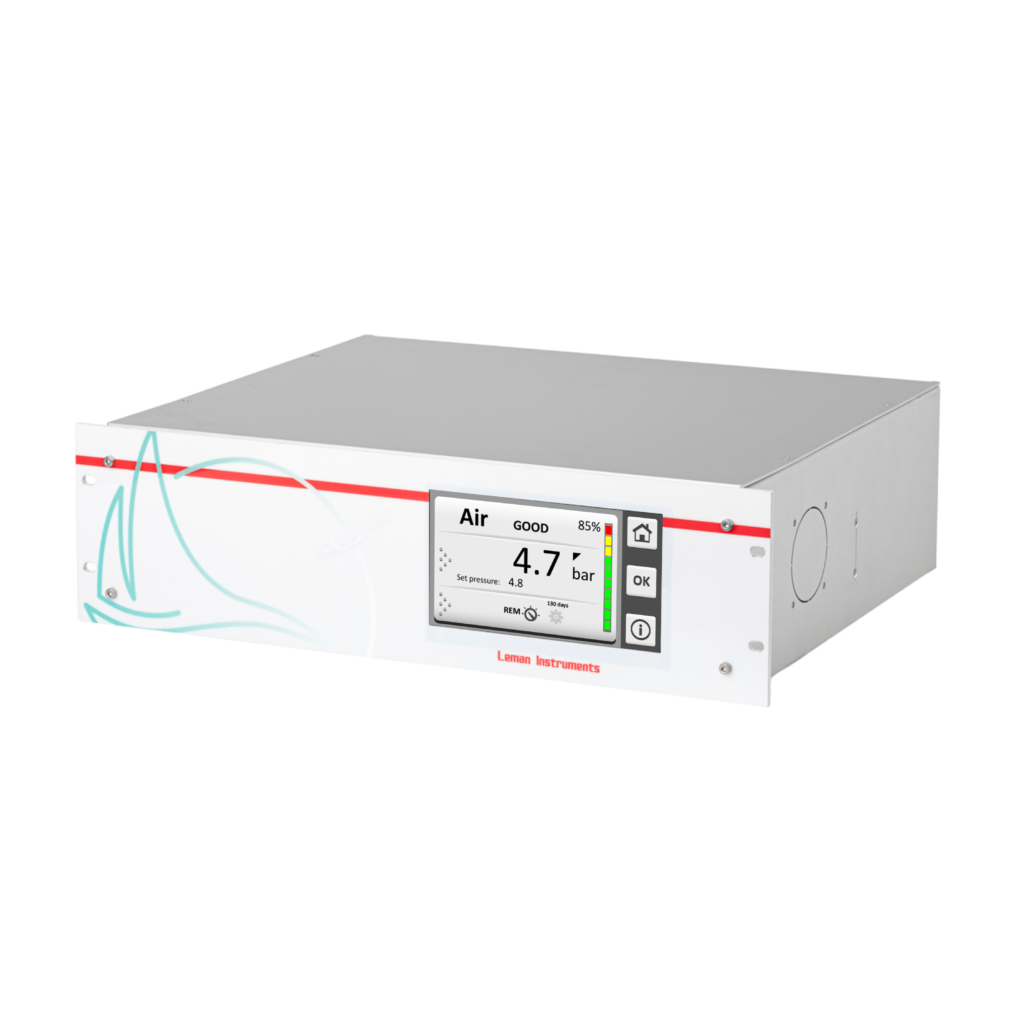

LEMAN Instruments designed the AERO50R product line of Zero Air Generators to fit almost any type of application that needs an independent supply of high-purity air close to the consumer in an elegant 19” casing with a full-color display and touchpad.

Compressed air is first filtered from particulates down to 5µm and partially dried. Then, it passes through a hot catalytic chamber to remove CO, CH4, and HC. Based on the field-proven Pressure Swing Adsorption (PSA) technology, air passes through a set of filters filled with molecular sieve and activated charcoal to be dried and cleaned from the last traces of HC.

After the purification process, the air is filtered of remaining particulates down to 0. 01µm, and pressure is regulated to the set value, between 0.5 and 7 bar (7 to 102 psig).

Models with outflow of 1.5 and 3 L/min AIR are available.

Each instrument has high-performance communication interfaces (Ethernet) to create a flexible gas network with local or central control.

The software’s focus on safety, automatic regulation, and intuitive and reliable communications makes the AERO50R easy to install, reliable, safe, and pleasant to operate.

Features

- Reduces in operation costs. Return on investment within 15 months.

- Improves resolution and detection limit. Provides high pressure stability.

- Zero Air is available 24/7 at constant purity. No contamination.

- Independent source of High Purity Air. Does not require complex piping. It can be easily moved around the laboratory.

- Long life

- Very safe operation, internal leak-test, automatic shut-down, protection against over-temperature.

- No handling, No storage, No cylinder rental fee

Gas

Models | AERO50 R-1.5 AERO50 R-3 |

LPM Outflow @1013 HPA / 20°C | AERO50 R-1.5: 1.5 LPM AERO50 R-3: 3 LPM |

AIR purity |

|

Dew point | < 10ppm |

Outlet Pressure | From 0.5 to 5 bar (7 to 72 psig) |

Site & Installation

Compressed AIR | Oil-free, dried compressed air; according to DIN ISO 8573-1 class 3 |

AIR pressure | Minimum: 1.5 bar (15psig) Maximum: 10 bar |

Manual control | Through a 7″ TFT-LCD color display with a touchpad located on the front panel. Display of major parameters, pressure, functioning status, and alarms. Intuitive navigation to functions by menus and sub-menus |

Remote control, Communications | Through Ethernet 10/100 network RJ45 |

Input & Output fittings | Stainless steel 1/4″ compression |

Power supply | Automatic switching from 90 to 260 VAC, 47 to 63 Hz |

Power consumption (max at full flow) | Maximum 700W |

| Ambient Temperate | +10 to +35 C |

Dimensions & Weight

Dimensions cm / in | L: 35cm / I: 41.5cm / H: 12cm (3U) L: 13.7in / I: 16.1in / H: 4.7in (3U) |

Net weight (kg/lbs) | 12kg / 26lbs |